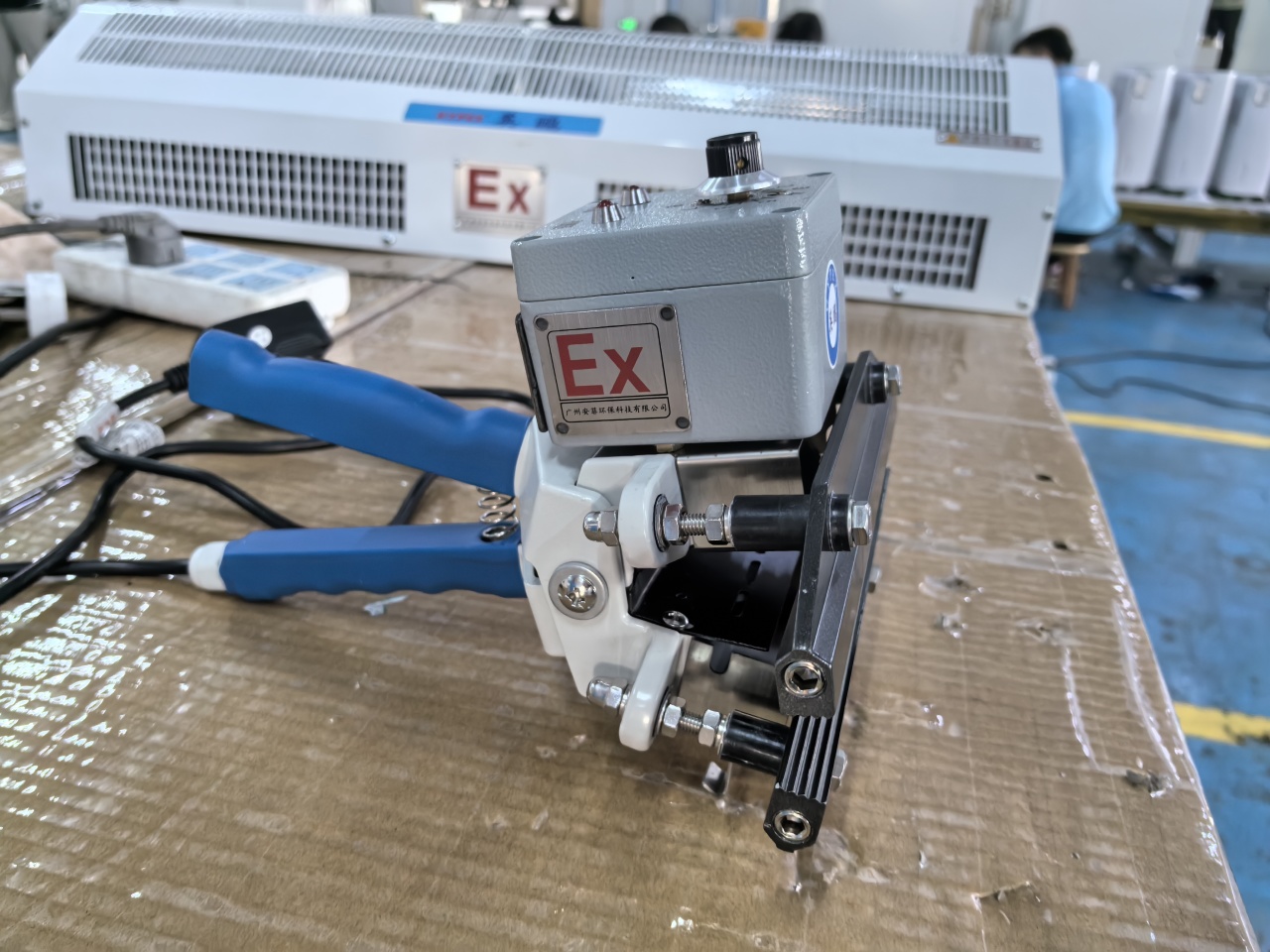

Understand Yingpeng Explosion proof Film Sealing Machine Safe and worry free, guarding every moment of production

2025-09-05 11:22:39

600

行业新闻

Yingpeng Explosion proof Film Sealing Machine is a packaging equipment designed specifically for environments with flammable and explosive risks. It is mainly used for sealing and packaging various plastic films, aluminum foils, and other materials. It can efficiently and stably complete sealing tasks while ensuring safe production, providing reliable guarantees for product packaging in related industries.

1、 Product features

Pedal start design, freeing hands and improving work efficiency by over 30%. Adjustable foot pedal force (5-15kg pressure optional), instant start in 0.3 seconds, sealing speed up to 40 times/minute, automatic temperature compensation function.

2、 Place of use

Suitable for regulating temperature in workshops, medical facilities, laboratories, food and other places with temperature control requirements.

1、 Product features

Lightweight body (net weight ≤ 1.2kg), ergonomic grip design (anti slip silicone wrap), portable charging design (lithium battery life ≥ 8 hours). Pulse heating technology instantly heats up within 3 seconds, with a special explosion-proof sealing pattern that supports sealing multiple materials with a thickness of 0.02-0.3mm.

2、 Place of use

Suitable for regulating temperature in workshops, medical facilities, laboratories, food and other places with temperature control requirements.

1、 Precautions before use

Ensure that the equipment is installed in a well ventilated, dry, and non corrosive gas environment, away from sources of fire and other high-temperature equipment. At the same time, it is necessary to ensure that the installation ground is flat and sturdy, able to withstand the vibration and weight generated during equipment operation, and prevent equipment tilting or shaking from affecting normal use and safety.

2、 Precautions during use

Operators need to undergo professional training, be familiar with the operation process and performance characteristics of the equipment, and strictly follow the user manual for operation. It is prohibited to arbitrarily change device parameters or engage in illegal operations, such as forcibly opening protective covers or touching heating components with hands during device operation.

3、 Precautions after use

After use, wait for the equipment to completely cool down and promptly clean the surface and interior of the equipment of any remaining film debris, dust, and other debris to keep the equipment clean. When cleaning, a dry and soft cloth should be used to wipe and avoid scratching the surface of the equipment with sharp tools. For difficult to clean stains, a moderate amount of neutral cleaner can be used for wiping, but it is important to ensure that the cleaner does not corrode the equipment.

4、 Maintenance precautions

Develop a regular maintenance plan for equipment, conduct comprehensive inspections and maintenance of equipment at specified intervals, including electrical systems, mechanical transmission systems, explosion-proof components, etc. Timely identify and resolve potential issues to ensure that the equipment is always in good operating condition.