Yingpeng explosion-proof coding machine, a new benchmark for coding, empowers hazardous production environments with safety and efficiency

2025-09-11 09:56:30

987

行业新闻

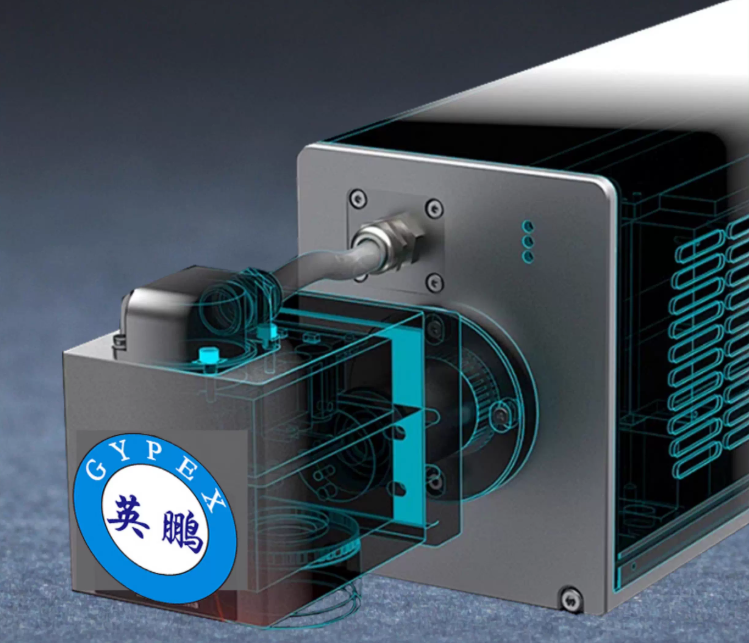

The Yingpeng explosion-proof coding machine is a high safety marking device designed specifically for explosive environments such as chemical, petroleum, pharmaceutical, lithium battery, and military industries. Through ExdeibmbIIBT4Gb explosion-proof certification, multiple explosion-proof technologies are adopted to ensure safe and stable product coding in flammable and explosive environments, meeting industry compliance and production traceability requirements.

Long service life, stable printing, all ceramic piezoelectric crystal structure, zero metal friction, completely eliminating electric sparks. 10 billion spray life (3 times that of ordinary nozzles), working in a wide temperature range of -20 ℃~60 ℃, suitable for environments from refrigerated warehouses to high-temperature workshops.

System stability, modular circuit design, main control module (hot swappable and replaceable), motion control module (± 0.02mm positioning accuracy). The nozzle drive module (adaptive voltage compensation), dual CPU parallel computing, completes fault switching within 0.5ms, and the intelligent diagnostic system warns potential risks 48 hours in advance.

1、 Equipment installation and environmental requirements

Be sure to install the explosion-proof inkjet printer in an explosion-proof area certified by a professional organization, ensuring that there are no flammable or explosive gases, dust, or other hazardous substances around. Stay away from high temperature and humid environments, choose a dry, well ventilated place without strong magnetic field interference, to prevent equipment performance from being affected by environmental factors and causing safety hazards.

2、 Preparation work before operation

Before each use, carefully check whether the explosion-proof coding machine casing is intact and whether the connections of each component are loose; Check the ink system to ensure that there are no leaks in the ink and solvent pipelines, and that the ink lines are stable and not offset; Check the surface of the nozzle, clean up residual ink, and prevent blockage from affecting the coding effect.

3、 Operation Specification for Running Process

Strictly follow the sequence specified in the equipment operation manual to turn on the device. First, connect the power and wait for the device to self check and confirm that there are no fault alarms. Then, start the ink system, nozzle, and other components in sequence. If any abnormalities occur during the self inspection process, immediately stop the machine to troubleshoot and prohibit operation with faults. Reasonably set parameters such as coding speed, font size, and printing position based on the material, size, and content requirements of the coding product. When adjusting parameters, it is necessary to do so when the equipment is stopped to avoid overloading or substandard coding quality caused by improper parameter settings.

4、 Equipment maintenance and upkeep

After daily use, promptly clean the surface of the equipment and residual ink around the nozzle to keep the equipment clean. Use specialized cleaning agents to clean the nozzle according to the prescribed process, to prevent ink from drying up and blocking the nozzle, which may affect the service life and coding quality of the equipment.

5、 Shutdown and storage precautions

If the equipment needs to be idle for a long time, the ink and solvent inside the equipment should be emptied, and the ink path system should be thoroughly cleaned with a cleaning agent; Store the equipment in a dry, ventilated, and non corrosive gas environment, and take measures to prevent dust and moisture; Regularly conduct power on inspections on equipment to prevent electronic components from being damaged by moisture.